3D-BOND 145 ABS/ASA Adhesive

3D-BOND 145 ABS/ASA Adhesive - 100mL is backordered and will ship as soon as it is back in stock.

Pickup available at Main Warehouse

Usually ready in 4 hours

Delivery and Shipping

Delivery and Shipping

For items available in stock orders are dispatched by the next business day.

Standard and Express shipping methods available.

3D-BOND 145 (Previously known as ACRI-BOND 145) is a clear, fast set, thickened adhesive suitable for bonding ABS and ASA to itself. Thickened formula leaves behind 25-30% dry residue allowing for some gap filling capacity when bonding 3D printed ABS/ASA parts.

If you’ve tried using what is available at your local hardware store like superglues or epoxies did everything right and the bond still breaks, you’re not alone. It’s a common first step when trying to bond together 3D Prints. While some CA adhesives will work well with 3D printed parts most off the shelf ones will not though. The difference with our adhesives is they chemically weld the two separate plastic parts together creating the strongest bond possible. If you want to step up bonding your 3D printed parts, try our 3D-BOND range.

Product Overview

3D-BOND 145 is a fast set, thickened, clear solvent cement ideal for bonding 3D Printed Parts made from ABS and ASA. Due to being thickened 3D-BOND 145 allows for some gap filling as it leaves behind solid residue when fully cured. It is also easier to apply compared to conventional solvent adhesives as there are no special techniques used to apply this glue. This adhesive can be applied via applicator bottle or brushed on.

3D-BOND 145 is a solvent cement meaning it works by chemically softening and fusing the surfaces of compatible plastics. This creates a true molecular bond where the two parts effectively become one solid piece after curing. This provides a strong virtually invisible bond that other 3D Printing Glues cannot achieve.

Applications and Uses

3D-BOND 145 has been designed for bonding the most commonly used 3D Printable Plastics. If your substrate is not listed in our material suitability tab due to it being mixed or other plastic material combinations, contact us as we are always trying new combinations or test on a small job before using in your production.

3D-BOND 145 can be used in a range of 3D Printed Plastic Jobs. For example: Joining Large Prints -that are too big for the print plate, Model Making, Repairing Broken or Failed Prints, Creating Hybrid Models – combining multiple materials, Architectural Model Building.

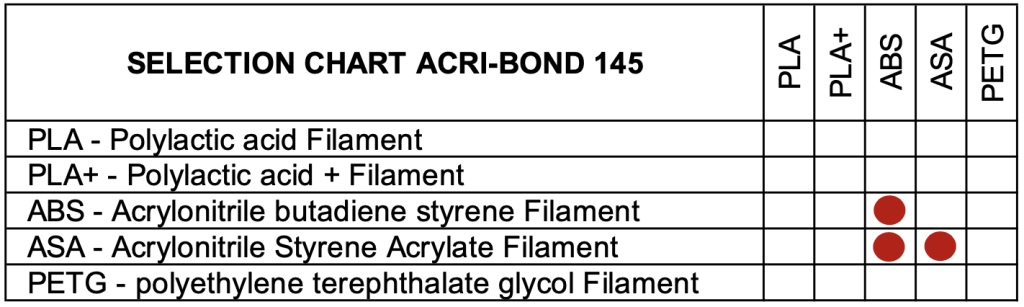

Material Suitability Chart

Tools and Accessories

For professional use of 3D-BOND 145 it is important to use the right tooling. We recommend using our 65mL Applicator Bottle with either a 0.8mm (green base) or 1.4mm (dark green base) precision dispensing tip. This will allow for maximum control of the adhesive when applicating. 3D-BOND 145 can also be applied through the 100mL Clear Applicator Bottle.

To help dispense the adhesive into the applicator bottles we stock small clear funnels and clear 100mL beakers.

This product can also be brushed on as a thin layer.

Technical Highlights

Instructions for use

Parts to be joined should fit without forcing and be clean, it is recommended to use ACRI-BOND CLEANER prior to applying any product to remove any dust and dirt. Apply adhesive with suitable applicator and assemble while parts are still wet. Press parts together in firm contact. 3D-BOND 145 forms an initial bond in about 3 minutes. Strength develops rapidly reaching full strength in 24 to 48 hours leaving about 25-30% dry residue. For a tutorial how to use please refer to our YouTube Chanel.

Shelf Life and Storage

3D-BOND 145 has a 2+ Year Shelf Life when stored correctly.

Store in a cool dry place out of direct sunlight to extend the shelf life of this product. Keep the open container tightly closed do not leave open as the adhesive will evaporate.